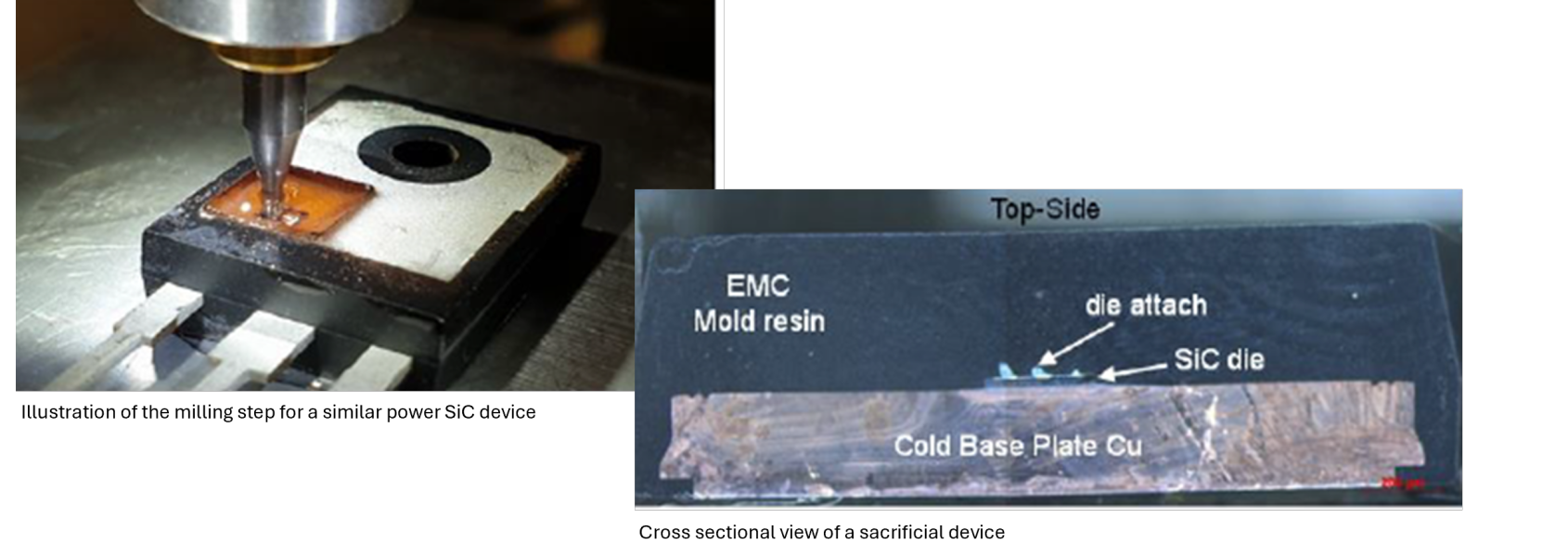

At ISTFA, Rosine GERMANICUS presented a paper about "SiC MOSFET micro-explosion due to a Single Event Burnout: analysis at the device and die levels". We at JPK Group are proud that we could support this paper with sample preparations conducted with a micro milling tool from our principle ULTRA TEC.

Please contact us for the complete paper or interest in Failure Analysis, Sample Preparation or FA Workshop on January 31, 2024 in Munich.

Contact: sales_de@jpkummer.eu

For device qualification in harsh environments (space, avionic and nuclear), radiation testing identifies the sensitivity of the devices and technologies and allows to predict their degradation in these environments. In this paper, the analysis of the electrical characteristics and of the failure of a commercial SiC MOSFET after a Single Event Burnout (SEB) induced by proton irradiation are presented. The goal is to highlight the SEB degradation mechanism at the device and die levels. For failed devices, the current as a function of the drain-source bias (VDS) in off-state (VGS=0V) confirms the gate rupture. For the die analysis, Scanning Electron Microscopy (SEM) investigations with energy-dispersive X-ray spectroscopy (EDX) analysis reveals the trace of the micro explosion related to the catastrophic SEB inside the SiC die. With a fire examination, similar to a blast, the SEM analysis discloses damages due to the large local increase of the temperature during the SEB thermal runaway, leading to the thermal decomposition of a part of the SiC MOSFET and the combustion with gaseous emissions in the device structure.